UPGRADE

Imeta has studied and developed many machines over many years. We produce a series of upgrades and modernization kits in order to improve seaming performances in different models of seaming machines.

COVER FEEDERS

The AP0158.4 Cover Feeder was designed by Imeta in the 1980s in collaboration with a major French can manufacturer, to allow any kind of cover to be fed, particularly “Easy Open” covers with tin plate and aluminum, onto high-speed seaming machines.

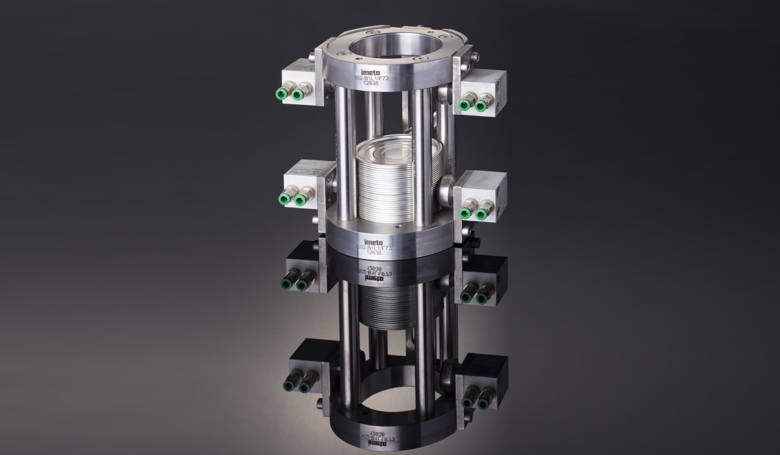

GEAR DRIVEN LOWER LIFTERS

Gear driven lower lifters are one of the upgrade kits designed by Imeta to improve the performance of old seaming machines. In particular, they have allowed producers to make using thinner cans that have now been on the market for many years due to their reduced cost.

Thanks to the experience gained with Angelus 60L seaming machines, various upgrades have also been developed for Ferrum F308, Comaco AGM4 and Lanico BF280 and Goetz 12P seaming machines.

Given the success of these kits, Imeta guarantees the availability of all such spare parts in our warehouse.

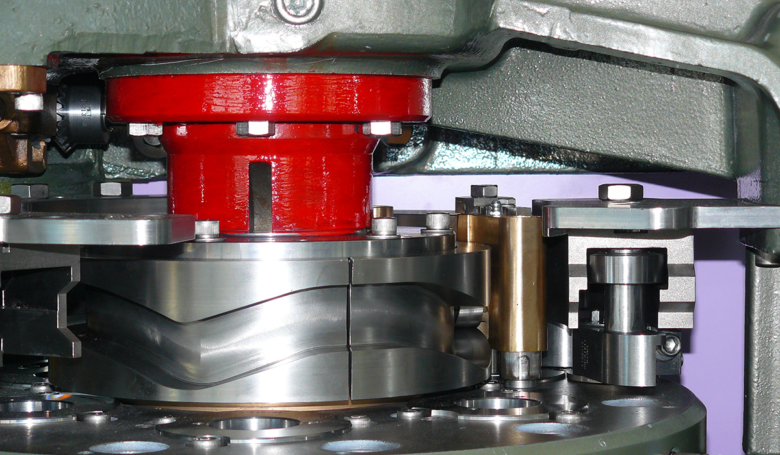

DESMO KIT FOR ANGELUS 60L

Imeta has created another kit named DESMO to improve the performances of old generation seaming machines. An Angelus 60L seamer equipped with a DESMO kit, together with the Gear Driven Lower Lifters and the Single Screw Cover Feeder, can reach the same performance as an Angelus 61H seamer.

INVERTER DRIVE GROUP

Another upgrade kits designed by Imeta is the Inverter Drive group. This controls the seamer’s start, speed variation and stop, allowing easier operations.

The kit provided by Imeta includes all the electronic and mechanical parts and a detailed instruction manual for correct installation.

Furthermore, the seaming machine will still be equipped with the hand-wheel for manual adjustment and emergency stop.