SEAMING CHUCKS, ROLLS AND ASSEMBLIES

CHUCKS AND ROLLS

The Imeta journey started with the non-OEM supplier of seaming chucks and rolls for both can-making customers and those end users closing and filling cans. Depending on whether the production is for a canmaker or for a cannery, Imeta uses different base materials that optimize performance. Typical materials include: standard steels (AISI D2, AISI 440, US2000 MC), sintered steel (K390, M390, Vanadis), special steels for specific applications (K360, Cromax, Calmax, Aisi 630, 15.5PH, Nicro 100) and Stoody Metal for increased resistance to deterioration and corrosion in conditions of maximum productivity.

Imeta also uses innovative surface coatings to both improve seam quality and increase the lifetime of our product itself. Imeta can offer CVD, PVD, wear-resistant chromium plating, Diamond 98 HRC, UCAR coatings.

We produce about 20.000 seaming chucks and 10.000 seaming rolls per year for our customer worldwide.

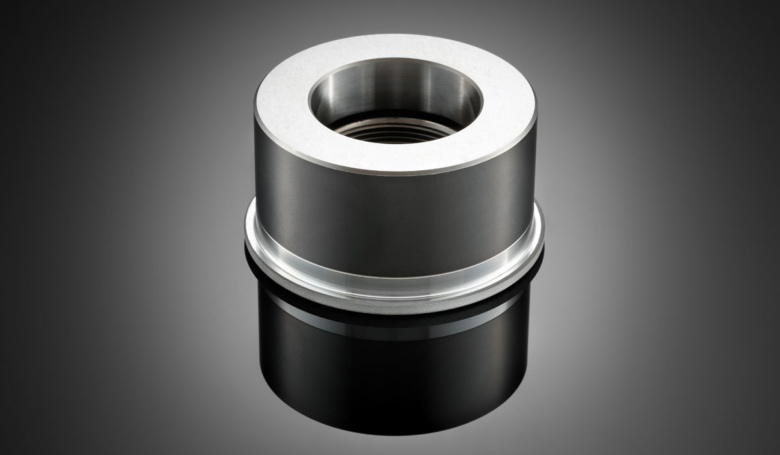

SEAMING ROLL ASSEMBLIES

STANDARD ASSEMBLY

In addition to the supply of bare seaming rolls, Imeta also offers as an optional service – the seaming rolls pre-assembled with their pins and bearings. Such rolls are provided already set and lubricated, ready to be mounted, allowing significantly reduced installation time. The assembly is carried out by skilled technicians using all the correct tools and equipment such as hydraulic press, induction heater, cryogenic assembly and dynamometric wrench. If certain old items (pins, bottom plates, dust covers) are still in good conditions, it is also possible to provide partial assemblies according to the client’s needs.

SPECIAL ASSEMBLIES

Thanks to our experience in this industry, Imeta has developed new assemblies for some rare and discontinued seaming rolls. These include the “Easy System” type roll for the Angelus P Series, and the “Super Seal” type roll for any seaming machines. These can reduce roll maintenance time and cost.

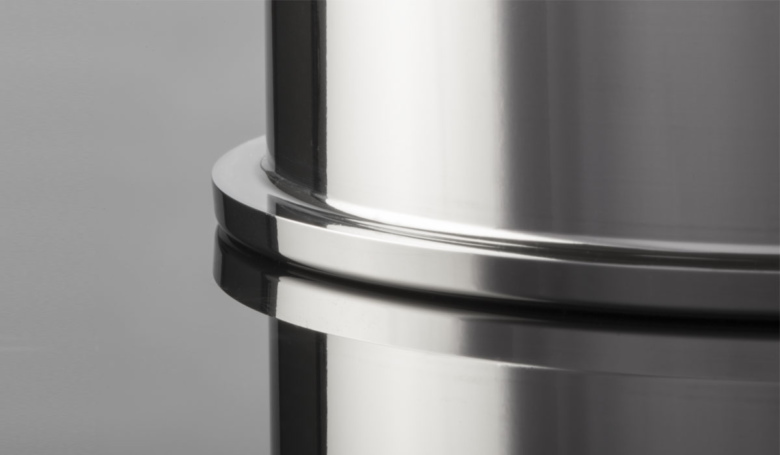

CERAMIC BALL BEARINGS

Ceramic ball bearings are increasingly popular with our customers as they are fully resistant to corrosion as both the external and internal races are made of stainless steel, while the inner cage is made of plastic material, which is resistant against high temperatures.

Thanks to the low friction of the ceramic balls, the seaming rolls require a reduced lubrication – up to five times less than standards.

This saves time for operators and maintainer, often with less machine downtime, and increased production.